The artisan method behind our white tuna preserves

Our white tuna preserves are made according to an artisan process learned and perfected by five generations. This "know how", combined with the rigorous selection of only the finest raw materials, means that our preserves have an outstanding quality.

How we make our white tuna preserve

The first step is to select the freshest and finest specimens as soon as the catch reaches the port. These are then transported to the factory without delay, where they are checked again for their freshness and quality and then sorted by size.

The innards and heads are removed manually. The fish is then boiled at an approximate temperature of 98ºC for about three hours, after which it is washed and left to cool.

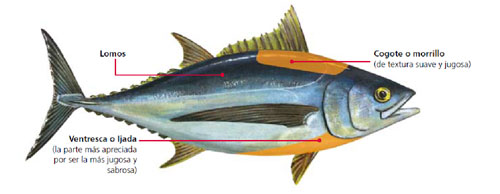

The white tunas are laid out on trays and then, one by one, the skin, scales and fat are removed. They are then cleaned again to eliminate any dark spots that may have been left behind. Next, the loins are separated from the neck and belly.

This step in the cleaning process, which is carried out manually from start to finish, is extremely important. Thanks to the skill and experience of our staff, combined with constant monitoring, all the "waste" is removed with hardly any damage to the fish, leaving whole and perfectly clean fillets. This is partly what gives our white tuna preserves their splendid appearance — that mouth-watering, savoury white meat for which they are famous.

The fish, this delicious fruit of the sea, is now ready for expert hands to start placing it in cans or glass jars.

Once in the container, the loins, neck or belly are covered with a specially chosen variety of olive oil or one of our sauces, and then hermetically sealed. The oil gives our white tuna preserves a soft, juicy texture.

Next comes one of the most important steps in the whole process: sterilisation. The can or jar is boiled at temperatures of 118/121ºC for the length of time required by the container. Sterilising the containers guarantees that the product will be preserved in perfect condition and with all its nutritional values. Finally, the containers are labelled, encoded, packed and palletised.

One very important aspect of this process is that every single white tuna specimen is subjected to strict quality controls and identified from start to finish. This means that we can identify each can or jar of our product and guarantee the outstanding quality of all of our preserves.

PARTS OF THE BONITO DEL NORTE (WHITE TUNA, ALBACORE)